On any given day, the University of Notre Dame’s Engineering Machine Shop will be crafting small chambers for mosquito research, sculpting a massive piece of metal for the Turbomachinery Laboratory, or providing expertise to a student or professor on the best, most practical design for a project.

The Engineering Machine Shop, located in Hessert Laboratory for Aerospace Research, specializes in close tolerance machining of large and small parts made from difficult-to-machine materials. The shop is open to the Notre Dame Research community, external academic institutions, and industry.

“Each member of our staff has more than 30 years of experience under their belt, so we have the capability to help students and faculty troubleshoot their project designs before anything physical is crafted,” said Eugene Heyse, Machine Shop Supervisor and Journeyman Machinist. “For many of the students, the Engineering Machine Shop offers them their first taste of making an object out of an original design.”

The shop includes a CNC Lathe designed to accommodate larger stock to make parts for the aerospace and energy industries, as well as two CNC Milling machines for heavy duty, high performance machining. Each of the machines operates with a computer program that allows the machinists to specify how they want a product to be crafted and then watch a three dimensional preview of each cut that will be made to complete the object.

“Our state-of-the-art, high-quality machines are essential to the research we support at Notre Dame. Because we cut materials for very specific research projects, we cannot afford errors,” said Heyse. “Therefore, with our computer programs, we are able to 3D preview and then rectify any faults before a single cut is made – saving our users time and expense.”

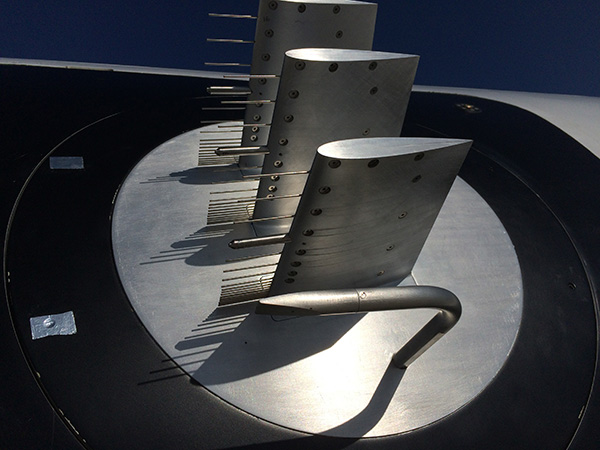

Eric Jumper, professor in the Department of Aerospace and Mechanical Engineering and director of the Aero-Optics Group, is the principal investigator for the Airborne Aero-Optics Laboratory (AAOL) and is investigating aero effects on airborne laser systems that involve flying two transonic Falcon 10 jet aircraft. Jumper has utilized the Engineering Machine Shop in developing various parts for his research.

“The Engineering Shop at Hessert has performed incredible work for the Aero-Optics Group that includes the manufacture of aircraft parts for Notre Dame’s Falcon 10, AAOL,” said Jumper. “These parts, which constitute major modifications to both the interior and exterior of the AAOL, are routinely approved by the Federal Aviation Administration both prior to and after manufacture and are then certified as flight worthy.”

The facility has gathered a valuable team of tool and die makers consisting of Heyse, Leon Hluchota, Terry Jacobsen, and Michael Sanders. They have completed projects not only for the University of Notre Dame, but also for other universities as well as private firms around the world.

“One of the best things about working with this group and being at Notre Dame is the research projects we get to contribute to,” said Heyse. “At the Engineering Machine Shop, we work on proprietary pieces as well as projects that are not even completely planned out yet. As the machinists, we get to see at the ground level some of the most groundbreaking advances happening on campus.”

If you would like to learn more about the Engineering Machine Shop, including how to start a new machining project, please visit https://ame.nd.edu/facilities-centers/engineering-machine-shop.

Contact:

Eugene Heyse / Machine Shop Supervisor and Journeyman Machinist

Hessert Laboratory for Aerospace Research / University of Notre Dame

heyse.1@nd.edu / 574.631.2551

About Notre Dame Research

The University of Notre Dame is a private research and teaching university inspired by its Catholic mission. Located in South Bend, Indiana, its researchers are advancing human understanding through research, scholarship, education, and creative endeavor in order to be a repository for knowledge and a powerful means for doing good in the world. For more information, please see research.nd.edu or @UNDResearch.