Notre Dame research is working with manufacturers to minimize warping in metal-printed parts

Professor Richard Billo, associate vice president for Research and professor of computer science and engineering

Professor Richard Billo, associate vice president for Research and professor of computer science and engineering

Three-dimensional printing, also known as additive manufacturing, isn’t just for plastics. In fact, Notre Dame researchers are working to 3D print a number of items, including metal orthopedic implants. However, when it comes to printing these medical devices, problems still plague the three-dimensional printing process but Notre Dame Research is working to solve these.

Richard E. Billo - associate vice president for research, professor of computer science and engineering, and affiliated member of the Wireless Institute - conducts research related to manufacturing, specifically in the advancement of technology for medical devices. For his latest research project, he is working with the Ohio State University, the University of Pittsburgh, and manufacturing partners like Johnson & Johnson, America Makes, and Indiana manufacturing company – ITAMCO – to improve the process for printing three-dimensional orthopedic implants.

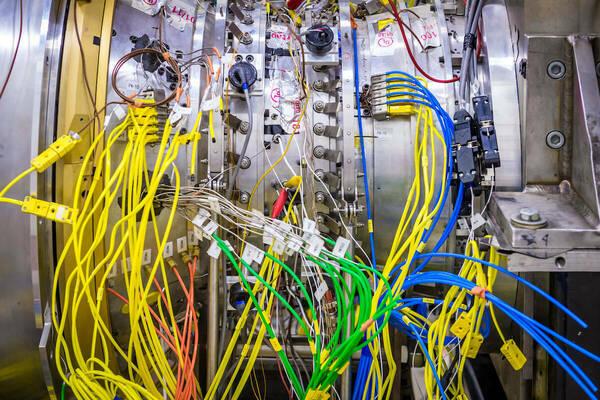

“With metal printing, the process stacks one layer after another, but the layers are cooling at different rates and causing stress in the product,” said Billo. “Printing metals can therefore lead to a warped and unpredictable product, which is unsuitable for devices that are made for medical uses.”

To overcome the challenges of the three-dimensional printing of metal, Billo and his team are developing optimization algorithms, with integrated process physics, with the objective to minimize stress and warping. This way, manufacturers can print consistent orthopedic implants in a cost-effective manner, which is imperative for federal certification.

Previously, Billo completed research in the areas of manufacturing, as well as information systems, working on projects such as the development of micro devices to regrow severed nerves, the creation of portable kidney dialysis units, and designing a system that supports national security. However, in his role as associate vice president of research, his goal is to support the research goals of other Notre Dame faculty through business development.

“I went into administration to help faculty find opportunities. Whether that means assistant professors working towards their first grants or supporting professors who are really creative, and open to having me be a part of their exciting ideas,” said Billo. “At the University of Notre Dame, people are full of energy and conducting research that will change the world and I like being able to help them accomplish that.”

Billo was named an associate vice president of research in 2013, where he manages Notre Dame Research Development. If you would like to learn more about him and his role, please click here.

Contact:

Richard E. Billo / Associate Vice President for Research

Notre Dame Research / University of Notre Dame

rbillo@nd.edu / 574.631.1196

research.nd.edu / @UNDResearch

About Notre Dame Research:

The University of Notre Dame is a private research and teaching university inspired by its Catholic mission. Located in South Bend, Indiana, its researchers are advancing human understanding through research, scholarship, education, and creative endeavor in order to be a repository for knowledge and a powerful means for doing good in the world. For more information, please see research.nd.edu or @UNDResearch.